Silicone UV resin, whose chemical name is photocurable organopolysiloxane, has the excellent properties of silicone and the high efficiency and energy saving characteristics of photocuring.

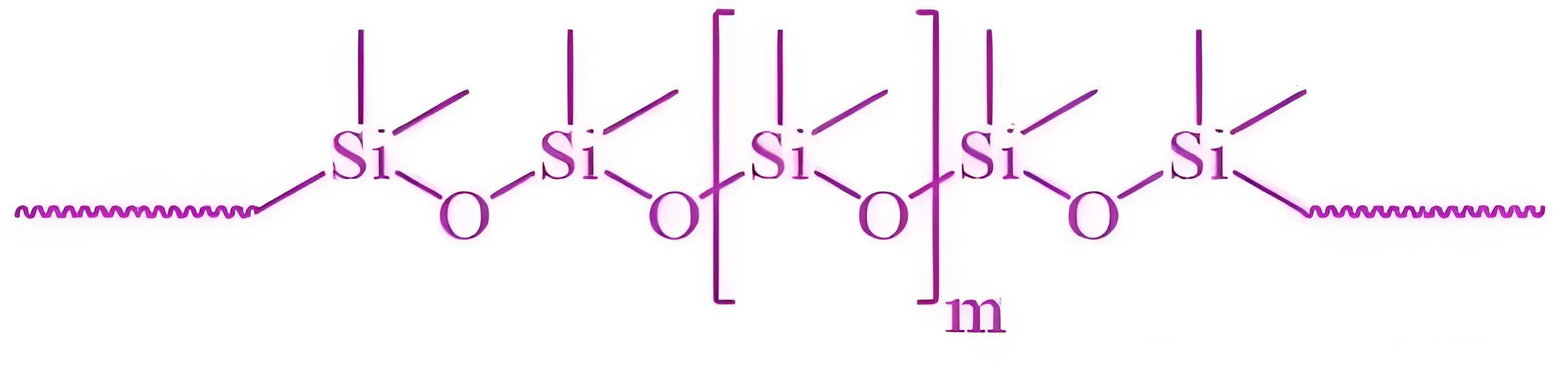

Classification of silicone UV resin (5 categories)

1: Thiol-olefin functionalized polysiloxane

2: Styrene polysiloxane

3: Vinyl ether functionalized polysiloxane

4: Epoxy functionalized polysiloxane

5: Acrylated polysiloxane

There are two methods for modifying acrylic resin with silicone: physical blending and chemical modification.

(1) Physical blending method

Adding silicone polymer directly to acrylic resin, physical blending method also known as cold blending method, is one of the common methods of material modification.

Features: Since the polarity of organosiloxane and acrylate is very different, phase separation is easy to occur, so the stability of the emulsion is not high, the storage period is short, and the improvement of its weather resistance and adhesion is not obvious. The use of compatibilizers can improve the compatibility of the two and achieve good blending of organosiloxane and polyacrylate systems.

(2) Chemical modification method

Chemical modification can improve the compatibility of polysiloxane and polyacrylate, inhibit the surface migration of silicone molecules, and make the two dispersed evenly, so as to achieve the purpose of improving the physical and mechanical properties of polyacrylate. Chemical modification methods can be divided into the following types according to the reaction mechanism: condensation (polymerization) method, hydrosilylation method, free radical copolymerization method, etc.

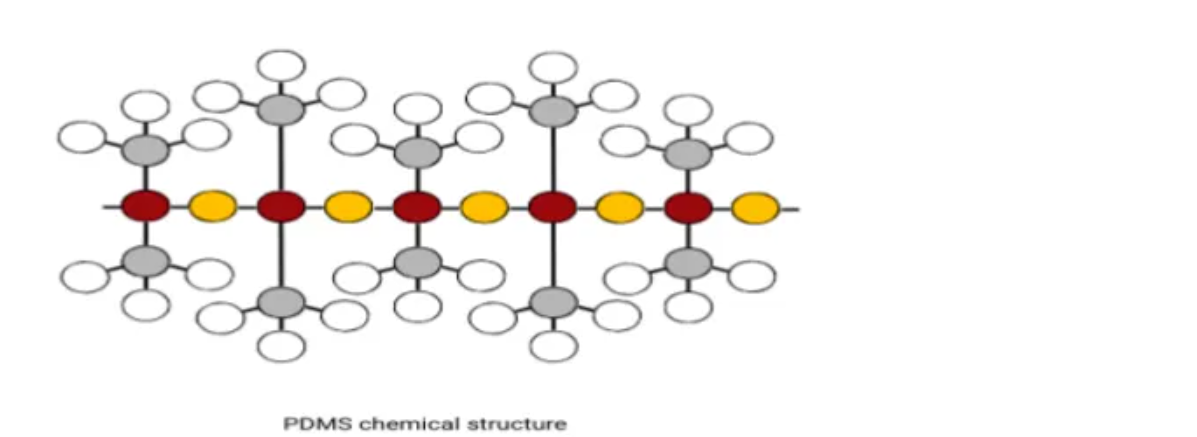

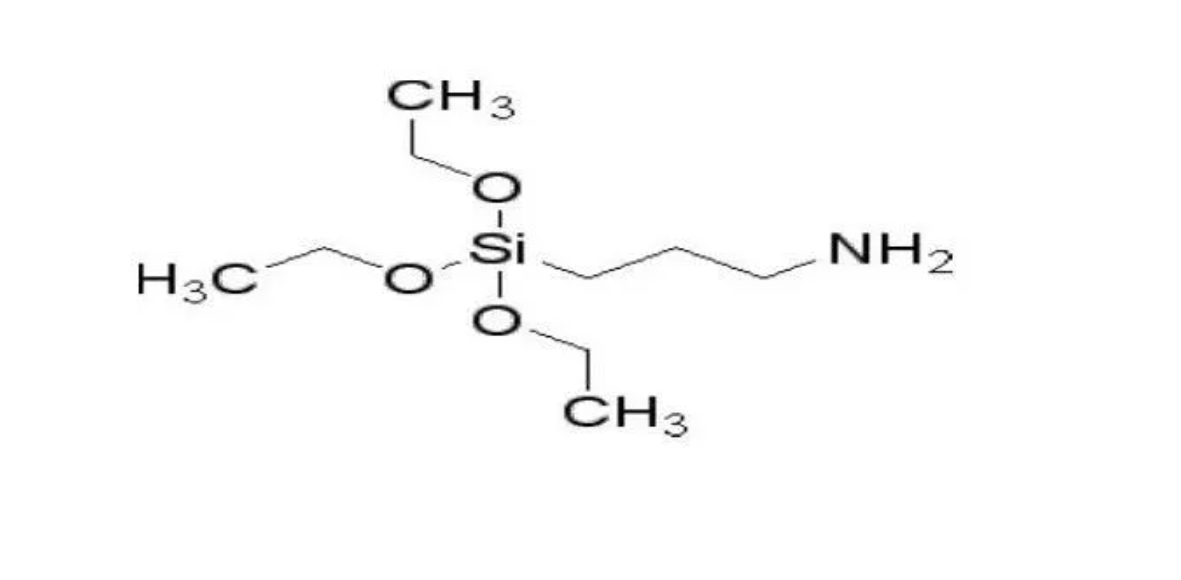

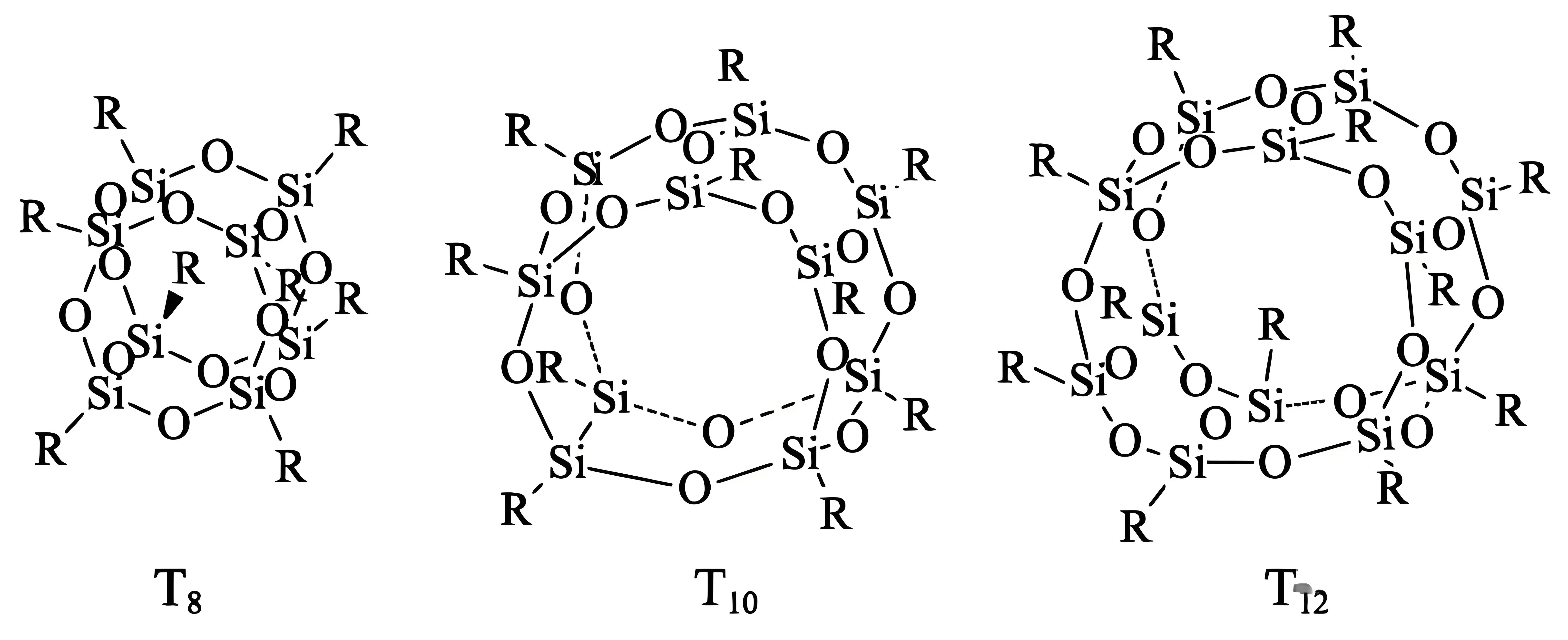

Commonly used silicone compounds for modified epoxy resins:

Polydimethylsiloxane (PDMS), silane coupling agents and organic-inorganic hybrid nanoparticles [polyhedral oligomeric silsesquioxane (POSS)], etc.

Example:

Application of polysiloxane in epoxy resin

① Improve toughness by introducing flexible Si-O bonds into its structure, making the polymer chain segments easy to rotate and effectively eliminating the internal stress of epoxy resin cured products, thereby achieving a toughening effect;

② Improve weather resistance. Si-O bonds have strong polarity and ionization tendency, which can effectively enhance the oxidation resistance of epoxy resin cured products;

③ Improve heat resistance. The bond energy of Si-O bond is much higher than that of CC bond, which is beneficial to improve the heat resistance of epoxy resin cured product:

④ Improve moisture resistance. Si-O bonds have lower surface energy and better hydrophobicity, which reduces the polarity of epoxy resin cured products.

Characteristics of silicone resin

1) One of the most outstanding properties of silicone resin is its excellent thermal oxidative stability. After heating at 250°C for 24 hours, the weight loss of silicone is only 2% to 8%, while that of polycarbonate is 55.5%, that of polystyrene is 65.6%, and that of epoxy resin is 22.7%. After heating at 350°C for 24 hours, the weight loss of general organic resins is 70% to 99%, while that of silicone resin is less than 20% [2].

(2) Another outstanding property of silicone resin is its excellent electrical insulation performance, which can maintain good insulation performance in a wide range of temperature and frequency. Generally, the electrical breakdown strength of silicone resin is 50kV mm, the volume resistivity is 1013~1015Ψ·cm, the dielectric constant is 3, and the dielectric loss tangent is about 10-3.